Weighing and Bagging Systems

Damodar manufactures high speed, high accuracy weighing and bagging systems.

These are semi automatic systems where the operator places the bag in clamping position. The bag gets clamped pneumatically and is filled with the desired quantity of material and discharged on a conveyor. The bag moves down the conveyor where a stitching machine is fitted. An operator is required to guide the bag at the stitching machine.

-

Optional features

- High accuracy, High speed

-

Printer / PC Interface

- Customized Reporting

-

Auto SMS / Mail of report

- End of line weigh checking

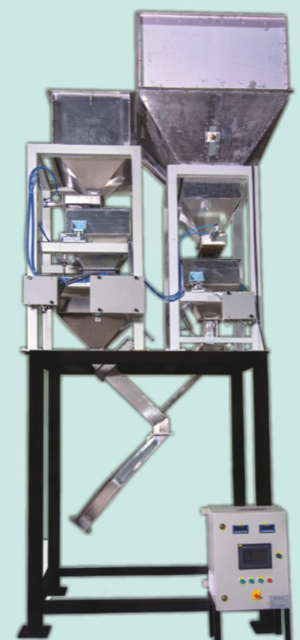

Flow Scale / Continuous Inline Weigher

-

For continuous online weighing of grain and other free flowing material. The system consists of one or two weigh hoppers which are continuously fed to a set level.

- Then feed is stopped for few seconds or diverted to the other hopper. The material is weighed accurately and discharged before feed is restarted and process repeated. The weight data is sent to a totalizer and displayed on the HMI screen.

- The system is designed to enable continuous flow of material in and out of the system so that the processing before and after the continuous bulk weigher is not disturbed.

- For accurate weighing and control of input and output in every shift

- Continous / Inline system to integrate seamlessely with the existing production line

- Load Cell based technology for accuracy with +0.2%

- PLC based system with Touch Screen controls. Easy operation, steady and reliable performance

- Rugged and aesthetic construction with SS contact parts

- Optional fetures - Web based data recording and reports

Rice Fortification System / FRK Blending System

- Approved by Bureau of Indian Standards BIS Licence number - CM/L 5100223074

- Load Cell based system

- Two separate Weigh Hoppers for blending Rice and FRK in a dynamic process.

- Option for integrated bagging machine

- Option for integrated blending of Broken Rice

- Continuous/ Inline system to integrate seamlessly with the existing production line.

-

Load Cell based technology for accuracy within +/- 0.5%.

- PLC based system with Touch Screen controls. Easy operation, steady and reliable performance.

- Inbuilt FRK Silo with level sensors and alarms to prevent operator oversight.

- Rugged and aesthetic construction with SS contact parts.

- Optional feature – Web based data recording and reports.

INNOVATION

INNOVATION

DESIGN

DESIGN

ECONOMY

ECONOMY